Description

The macerated & sized leaves are fed in to the short feed PVC conveyor belt from the up-stream process equipment, where it is spread at desired thickness to the desired width of the belt, with the help of an incorporated helical spreader on the feed conveyor of CFM. This spread sheet of leaf mass drops in to the feed end of the fermenting surface and carried at desired thickness reaching the discharge end after the set residence time on the surface. Humidified air, being constantly controlled at arround 95% R.H from a suitably designed humidificationunit consisting of a misting/air-washer chamber and water pump, is supplied by a cenrifugal blower fan to the modular plenum chambers under the moving belt through a ducting network. The oxydation/fermentation process can be regulated through individually dampers in the inlet ducts to each of the modules or maintaining a set temperature profile of leaf on the moving surface along the total travel length, either manually or electronically. Wide ranging speed/time variation essential for proper fermentation can be achived using the incorporated effectively & sturdily designed variable drive systems of several options to chose from.

* Modular design with complete stainless steel construction of hoppers, guards and all contact parts.

* PES belt of higher opening percentage allowing complete air penetration through the leaf for proper fermentation as well as cooling of tea bed.

* Each module has individual dampers to control desired air pressure. Twin duct design with perforated plates which allow uniform delivery of humidified air.

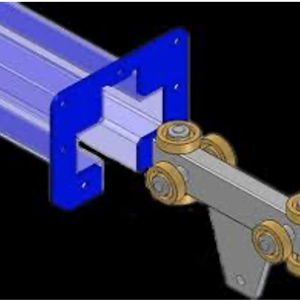

* Up turner drive mechanism to avoid uneven fermentation

* 18″ inclined Feed conveyor with PVC belt having zero tracking mechanism and helical spreader arrangement

* Nylon cleaning brush to keep the carrying surface absolutely clean and eliminate slippage

* Available in stage and dual stage design