Description

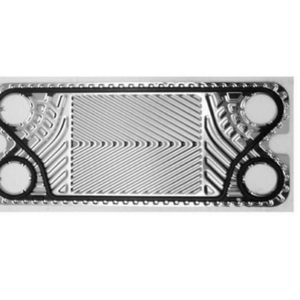

Compact heat exchangers for extreme temperatures, pressures and special designs that exceed gasket limitations. They offer high performance, small sizes and minimal maintenance. The exchangers can handle liquids, gases and two-phase mixtures at very high pressures and at low and high temperatures. They are manufactured to meet customer needs for the highest quality and efficiency. Tranter offers a wide variety of Welded PHEs for applications which limit the use of gasketted PHEs due to gasket incompatibility or due to high pressure and temperature operating conditons. Tranter’s range of Welded PHEs consists of MAXCHANGER, small sized welded heat exchanger for oil cooling, subcooling applications, SUPERMAX, circular plate heat exchanger, ULTRAMAX, a highly versatile product which can handle very high flow rates and Platecoil, prime surface heat exchanger used for a variety of heat recovery applications.

Tranter’s all-welded heat exchangers are used for liquid-to-liquid, steam-to-liquid, gas-to-liquid, gas-to-gas and refrigerant applications (including ammonia). Requirements up to 538°C operating temperature and 70 bar working pressure can be accommodated.