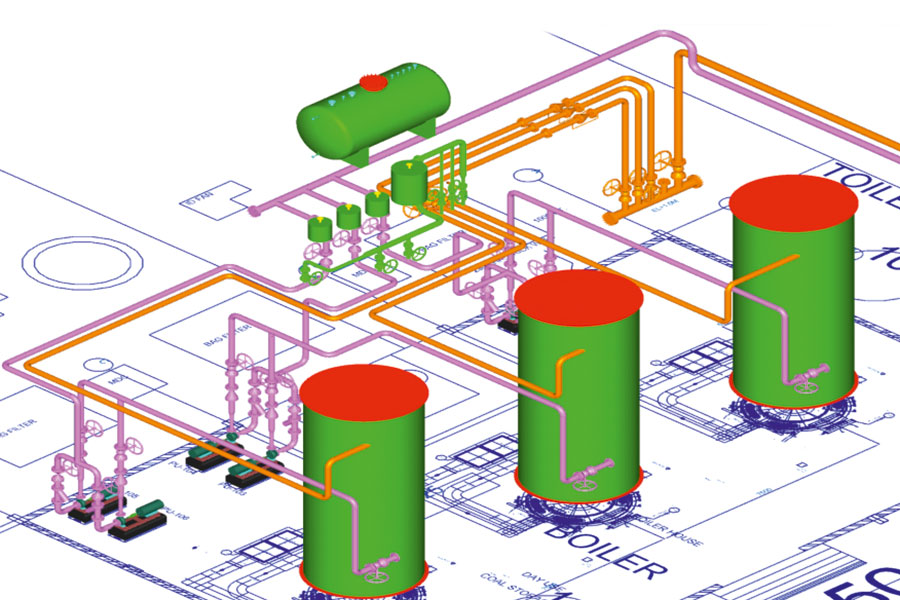

Our team of experts ensure that the power plant runs optimally with a guarantee for its performance parameters i.e. plant availability, power generation, auxiliary power consumption, heat rate and emission levels.

Offerings:

Comprehensive O&M

O&M management

Training services

Commissioning services

Chemicals, consumables and spares

Benefits:

Fixed costs

Extended plant life

Plant operation flexibility

Increased operating safety

Performance improvements through innovation and cross-learning